Trowels are used to finish a concrete floor. They use pressure to make the surface flatter and smoother. Surfacing ensures the finish of the slab suits its intended purpose. Learn more about how to succeed with troweling in the guide below.

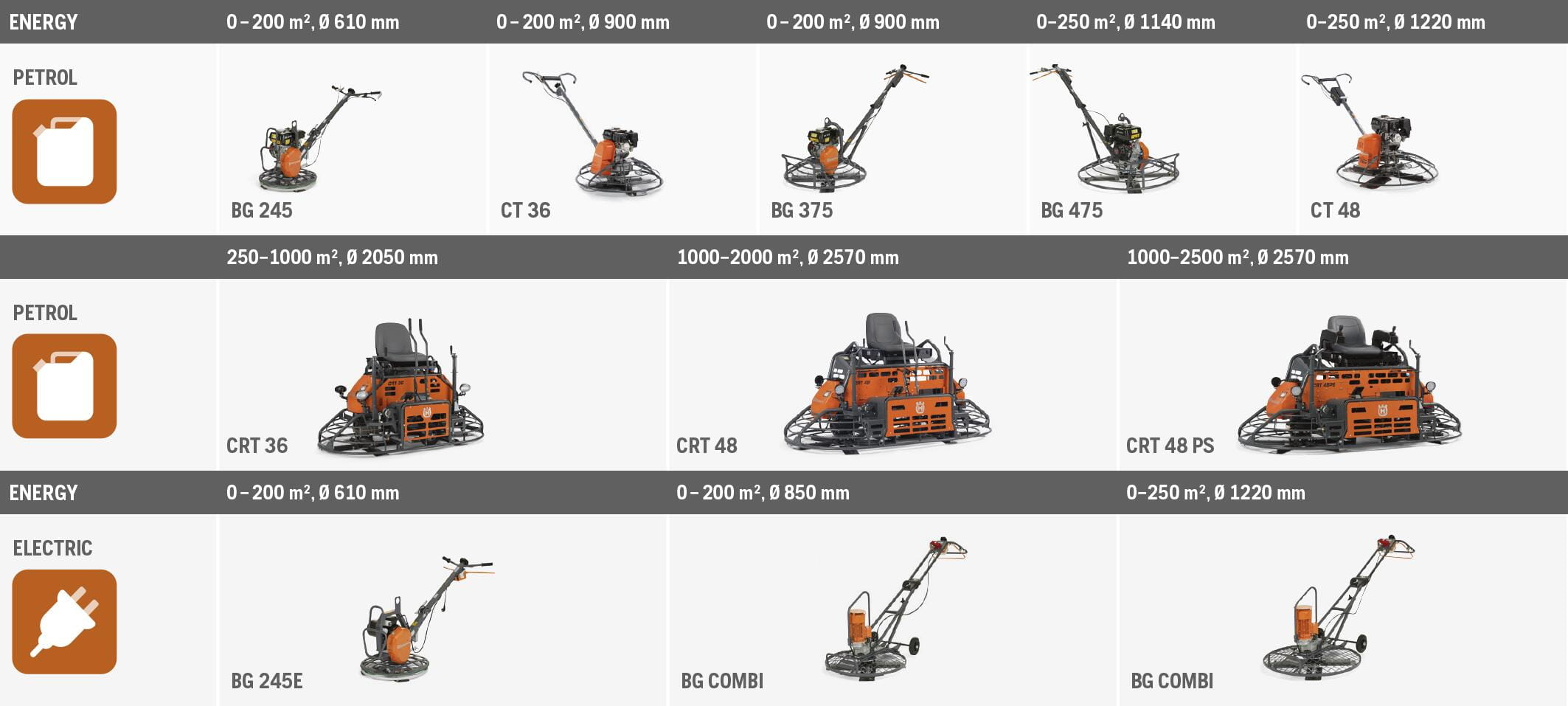

Consider the following factors when choosing troweling equipment